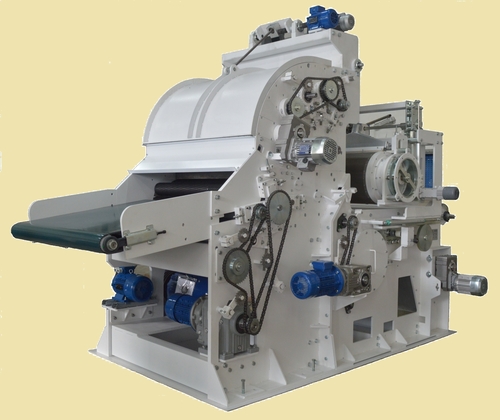

THE NEW AIRLAY CARD,

mod. CA 300 which had been presented during last years's ITMA 2015 in Milan, is now ready for customer trials.

Please contact us: Tel: +39 055 9198257 , Fax: +39 055 9194820

or by e-mail: info@mecatex.com

FOR FURTHER DETAILS OF THE CHARACTERISTICS ABOUT THIS MACHINE CLICK HERE

The airlay card is particularly indicated for the production of voluminous materials as used in automotives, mattresses, furniture, upholstery, footwear and filters.